Cyrus Audio is a famous British hifi brand, renowned by enthusiasts for their quality hifi amplifiers, CD players, DACs and streamers. Cyrus design, engineer and manufacture essentially all of their hifi products here in the United Kingdom, an operation that allows them to ensure the best possible standards of build quality and sound integrity.

Alex and I were invited down to the Cyrus factory in Huntingdon to get a feel for how the company operates and learn more about their range of products from the people who design them. The day began with a cup of coffee and a general chat about the company and the way in which they design their products. The PCBs for Cyrus products are made in Nottingham, hand-assembled by skilled engineers to Cyrus' precise schematics before being shipped to the factory in Huntingdon to be integrated within a product.

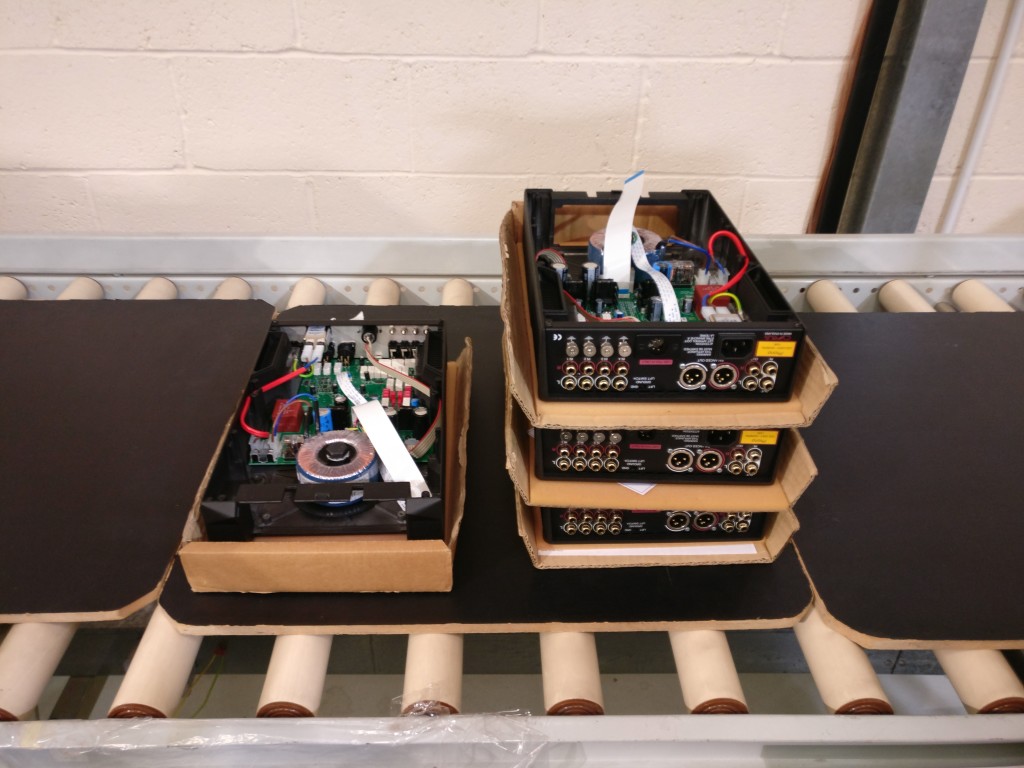

The factory space is relatively small, especially when considering the calibre of product that Cyrus build and when considering the factory size of their competitors. The majority of the Cyrus catalogue is assembled upside down, by hand and by one engineer from start to finish. This method Cyrus say allows for magnetic fields to point downwards and avoid compromising the sound quality while also making for a more efficient heat dissipation. As heat is able to rise upwards to the top of the unit, it doesn't need to pass chipsets and printed circuit boards on its way. The benefit of having a single engineer responsible for the assembly of a unit is a tenfold improvement in actual build quality and quality control.

Once put together, each unit undergoes a series of extensive tests to ensure that it's functioning correctly and doing so to Cyrus' extremely high standards. One such test is to check the power-handling capability of the machine where an engineer will slowly raise the voltage going into the unit up to 240v, guaranteeing that it's safe for mains circuits.

To guarantee that every connection is working as it should, Cyrus use this intelligent machine to run a series of commands and checks across every input and output of each machine, whether it be CD players, amplifiers, DACs, etc.

For CD players, a rather simple yet highly effective testing method has been devised to confirm the loudness of the internal mechanisms. In a sound-proofed box is a completed Cyrus CD player, which is used as a control. Once an engineer has finished assembling a CD player, it is put into this sound-proof chamber and fed a disc. The engineer will then stick their head into the box and compare the sound of their completed CD player with the fully accurate control unit to confirm that they are both making the same operating sound. If the recently assembled unit is louder for any reason or making a different tone or noise, then it is taken back to the bench and re-assembled until correct.

Following the factory tour and a bite to eat, we were treated to an in-depth conversation with David at R&D who went into great detail about the design process of a Cyrus product from start to finish. It was great to have an insight on this part of product development and get a real understanding of how much time is needed to design each element of a product, from software licensing and firmware coding to actually sourcing physical parts for the hardware.

After the informative discussion with R&D, we gathered into Cyrus' cosy demonstration room to listen to some music. Using an eclectic range of tracks, we worked our way through Cyrus' amplifier range starting with the One through to the 6 DAC and finally the Mono X 300 Signature Mono Blocks to compare the differences in sound and the differences in technology that cause the sound quality improvement at each jump. It was really interesting getting to grips with Cyrus' design philosophy on amplification and hearing an in-depth explanation of how and why they employ certain methods at certain levels to achieve a better sound overall. One such example is the way that the Cyrus One is able to offer a superior sound quality when compared to other Class D amps through the use of intelligent innovations like SID (speaker impedance detection).

The Cyrus demo room is home to their many trophies and accolades, neatly arranged at the back of the room. One of my personal favourites was the original Cyrus One and it's 'Amplifier of the Year 1988' award from The FBA Industry Awards.

After a really productive and informative day, we left the factory with a greater understanding of just how precise and rigorous the Cyrus design and manufacturing process really is. It was brilliant to see how close-knit the team is and how much they believe in the Cyrus brand. This commitment to building an outstanding product is evident with every release, whether it be a streamer like the Stream X Signature, a CD player such as the CDt, or an amplifier like the 8 (Mk II) DAC